Guest Blog: Rhamnolipids promise a renewable revolution

31st May 2017

Environmental impact is something that has become increasingly important for organisations and consumers in recent years. It is a topic discussed on a global scale by world leaders, and an issue of contention for many.

For some chemical engineers it has provided an opportunity for them to use their knowledge of chemical processes to create environmentally-friendly alternatives to the products we rely on daily.

In today’s blog Dr Dan Derr gives an insight into biosurfactants – which he hopes will spark a 'renewable revolution' in the fast-moving consumer goods industry.

Name:

Dr Daniel Derr

Current Position:

Project Leader, Internal Research & Development, Logos Technologies

Bio:

Dan gained his PhD from Colorado State University, and went on to study bio-based jet fuels and photocatalysis at General Electric’s Global Research.

Following this, he led an integrated BioRefinery effort called the Corn to Cellulosic Migration (CCM), focusing on the migration of billions of dollars of capital deployed in today’s corn ethanol industry toward cost-effective production of greener ethanol from corn stover, switchgrass and woodchips.

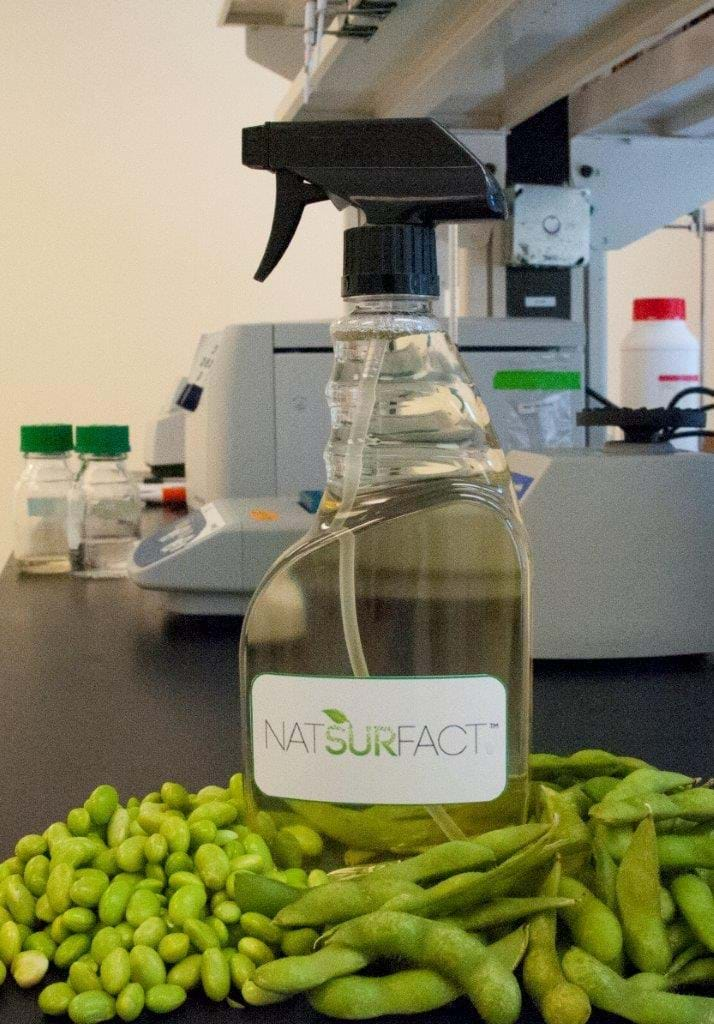

Now working for Logos Technologies, Derr is currently focused on NatSurFact® - a rhamnolipid-based line of biosurfactants.

Whether it’s fuel or plastics, the move to replace petroleum-based products with renewable alternatives is gaining momentum.

This is due, in part, to consumer preference - shoppers want products that are better for the environment. But it’s companies too. They’ve discovered that eco-friendliness often translates to efficient and sustainable (and thus profitable over the long term) business practices.

In my own field of surfactants, I’ve been seeing this green trend as well, and its potential economic and environmental impact is substantial.

Surfactants sit at, and change the nature of, interfaces between two phases of material. So, for example, they can keep a mixture of oil and water from otherwise separating into separate layers.

Outside the lab, in the real world, they help soaps, shampoos, and assorted cleaners foam and lift away dirt from surfaces. They give toothpaste that pleasant feel, hold together the chemical components in cosmetics, and help liquid agricultural sprays spread evenly over crops. Any home or workplace will have products with surfactants in them.

Conventional surfactants are made from petroleum-based synthetic chemicals, which are harsh on the skin and damaging to aquatic life. This is why a number of companies have been developing bio-based surfactants, made from chemically combining renewable pieces - or even better, biosurfactants, which are created naturally with microbes.

There are several types of biosurfactants, but an especially promising class is rhamnolipids. Besides being renewable and eco-friendly, rhamnolipids produce strong, high-foaming cleansers that are mild to skin and eyes. The problem is that they’ve been perceived to be too expensive to manufacture. Indeed, aside from the bio-fungicide Zonix, no commercially available product seems to feature rhamnolipids.

Still, some companies are excited enough by the properties and prospects of rhamnolipids that they are looking for ways to commercialize them.

Our approach has been to invent an end-to-end manufacturing process that is environmentally friendly and will work well at large scale, producing commercial quantities of inexpensive biosurfactant.

Basically, we feed triacylglyceride oil - vegetable oil or some non-food analogue - to bacteria, which consume it and excrete rhamnolipids into a fermentation broth, in a process similar to how beer is made.

Our proprietary fermentation approach is very efficient compared to the results we’ve been hearing about from others in the field. And we have invented a proprietary way to make a concentrated product inexpensively.

So far, we have submitted several patents on our NatSurFact process, and we have been proving it out at larger and larger scales since we first ran our pilot plant early in 2014. The run results we’ve obtained to date, when fed into a model that predicts production costs for a full-scale plant, show that our rhamnolipid-based products are cost-competitive with conventional surfactants.

Right now, we are looking for manufacturing partners to help us get to full scale. Once that final hurdle is cleared, we are confident you will start to see, at long last, rhamnolipids replacing petroleum-based surfactants in everything from makeup and household cleaners to fungicides.

If you would like to be featured on the IChemE ChemEngBlog get in touch.