Guest Blog: What happens to the batteries when cars die?

6th March 2017

Not all chemical engineers end up on an oil rig. It’s a profession that can pull you in various directions, to various places and companies, tackling various problems. No chemical engineer is the same – that’s the beauty of it.

In a relatively short time Amrit Chandan has established himself as a serious entrepreneur. His company, Aceleron, uses fundamental chemical engineering principles to tackle very real challenges in our society. In today’s blog post Amrit tells us, in his own words, about his chemical engineering journey and why Aceleron, a business under 18 months old, has been turning heads.

Name: Dr. Amrit Chandan

Qualifications:

PhD in Chemical Engineering (Hydrogen, Fuel Cells and their Applications)

BSc (Hons) Chemistry Class I

Job Title:

Co-Founder and Business Development, Aceleron

Bio:

Amrit is an experienced engineer specialising in electrochemical technologies, specifically fuel cell technology. He co-founded battery reuse company, Aceleron in 2015. Aceleron seeks to provide low cost energy storage to developing regions.

Previously, he worked as a Technical Specialist in low carbon vehicles at Cenex, providing expertise and specialist knowledge for Cenex’ programmes and demonstrator trials.

Amrit has published 10 academic papers on a range of topics from marketing to fuel cell technology development, and was named Business Quarterly Magazine’s Entrepreneur of the Year 2014. Most recently, Amrit was featured on the Forbes 30 Under 30 Europe Class of 2017.

Change! The need to be a positive force for change and to leave the world a slightly better place is very important to me, and one of the reasons I got into chemical engineering.

When I was making the decision to study chemistry or chemical engineering at University the choice seemed obvious – chemistry, so I could create great, stepwise, disruptive changes in industry.

However, after sitting through numerous lectures, each more esoteric and theoretical than the last, I knew I needed to do something more practical. Therefore, the natural option would be to study fuel cell technology - at least that’s what I told myself as a naïve undergraduate.

As with many future energy technologies, like fusion, the inside joke within the fuel cell sector is that they are always just 10 years away or “right around the corner”.

This was the case when I started my PhD study and was still the case when I finished my study there 4 years later at the Centre for Doctoral Training in Hydrogen, Fuel Cells and their Applications in Chemical Engineering, University of Birmingham. However, it was the combined fundamental knowledge of electrochemical processes as well as the larger scale understanding of process engineering/thermodynamic processes that finally landed me on Aceleron.

Aceleron began as lots of ideas do - with a conversation.

What happens to the batteries when cars die?

UK/EU legislation dictates that end of life lithium-ion batteries must be recycled in an environmentally friendly fashion and is the responsibility of the OEM (Original Equipment Manufacturer).

When one considers that potentially these batteries have upwards of 70% capacity remaining, and the carbon emissions which go into producing the batteries, this waste is a huge problem. The problem was only going to get worse due to the increasing number of battery electric vehicles being sold.

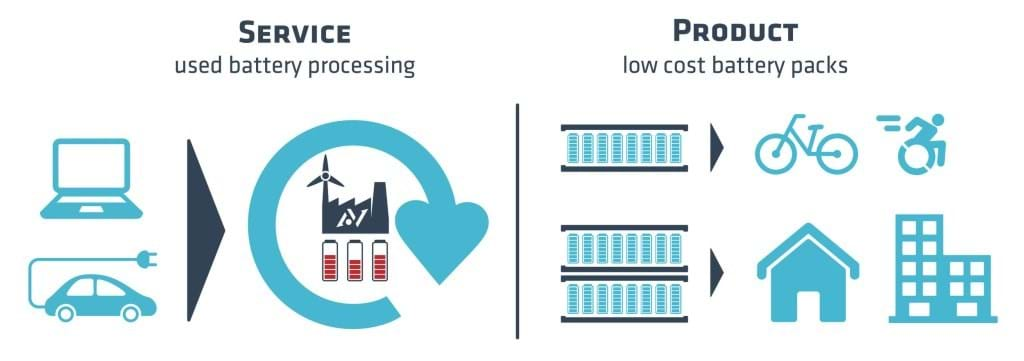

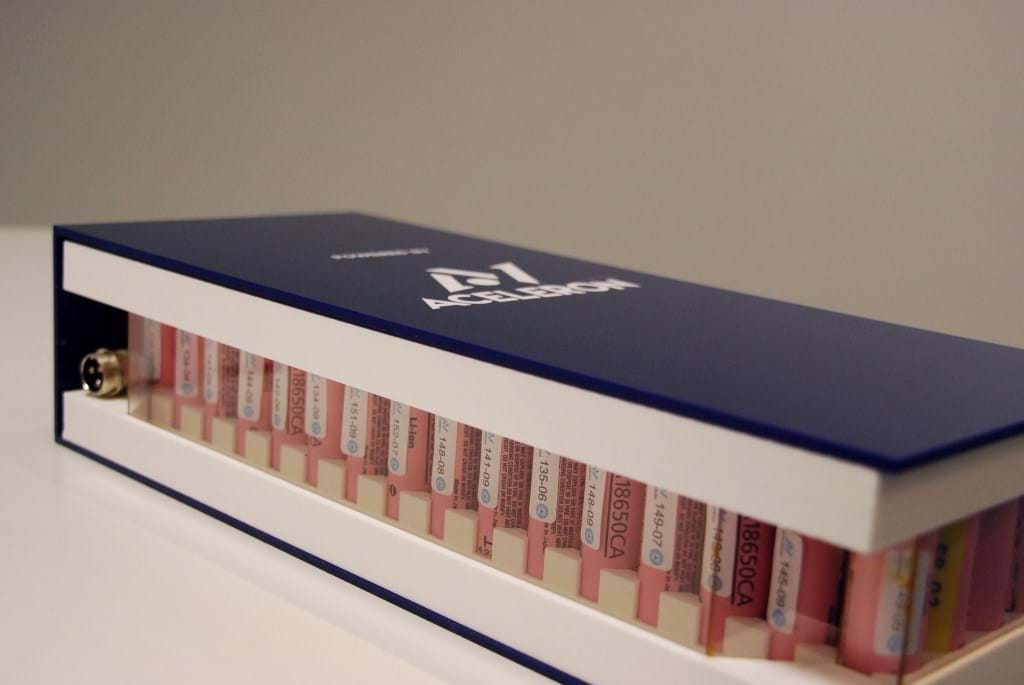

Using the process engineering skills I’d learned at University, we designed a process to transform waste batteries into re-manufactured battery packs, using a combination of testing methods such as electrochemical impedance spectroscopy. We started a trial in partnership with Brunel University, to test the process on a small scale - testing and processing ca. 200 lithium ion batteries from staff laptops. This was followed by the building of a prototype battery pack used to run a demonstrator e-bike.

The trial was such a success we have now formed several partnerships with waste management contractors to process consumer electronics grade batteries into remanufactured battery packs.

Recently, Aceleron won an InnovateUK grant to scale up our process to handle electric vehicle lithium battery packs.

Our packs are created with the circular economy in mind. Our ultimate vision is to offer the energy as a service rather than just to sell a battery.

To achieve this, we would like to provide low-cost energy storage to developing regions, where access to cheap batteries can be the difference between a person using a solar panel or a polluting diesel generator.

Our battery packs will be a similar price to brand new lead acid batteries and significantly cheaper than brand new lithium ion batteries.

Already we are talking with companies in the Caribbean, Central America and Sub-Saharan Africa to see Aceleron technology put into homes alongside solar and biomass technology.

This year Carlton and I were shortlisted on the Forbes 30 Under 30 Europe Class of 2017. We were thrilled, and can only thank our mentors, the Autodesk Entrepreneur Impact Program and Shell LiveWIRE grant funding for their support and advice. The most amazing part of all this is to look back and see how much we have achieved since December 2015, when Aceleron was just an idea.

We still have a long way to go, but I am confident that Aceleron has the potential to change the world.

If you would like to be featured on the IChemE ChemEngBlog get in touch.