Five chemical engineering research stories from August 2016

5th September 2016

To help you stay up-to-date with the latest achievements from the chemical engineering research community here is our monthly installment with some of the latest stories.

Here are five stories of amazing chemical engineering research and innovation:

Lab-on-a-Stick

A team from Loughborough University and the University of Reading have developed a portable power-free test for the rapid detection of bacterial resistance to antibiotics, or as they call it a ‘Lab-on-a-Stick’.

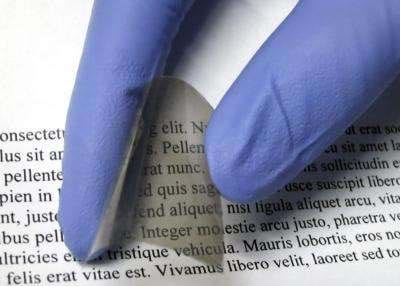

The test, published in the Lab on a Chip Journal, is an inexpensive microfluidic strip – comprising of tiny test tubes about the size of a human hair – capable of identifying bacteria found in urine samples and checking if they are resistant to common antibiotics. The team say that ‘Lab-on-a-Stick’ is easy to use and cheap to make, and the transparent microcapillary film is suitable for naked eye detection or measurement with portable, inexpensive equipment such as a smartphone camera.

Dr Nuno Reis, Lecturer in Chemical Engineering at Loughborough University, said: “This is a major step towards miniaturising complex, routine microbiological and clinical tests that cannot at the moment be performed outside of the laboratory setting. Our secret is simplicity. We have shown how microengineered film material made from a very transparent plastic with special optical properties, makes it easy to perform laboratory tests without lab equipment.”

New flexible material can make any window 'smart'

Chemical engineers from the Cockrell School of Engineering at The University of Texas at Austin have invented a new flexible smart window material that, when incorporated into windows, sunroofs, or even curved glass surfaces, will have the ability to control both heat and light from the sun.

Their work, published in Nature Materials, follows on from extensive investigation in to smart windows (see our blog on A new window on Chinese New Year). The team, led by Delia Milliron, an associate professor in the McKetta Department of Chemical Engineering, developed a new low-temperature process for coating the new smart material on plastic. This makes it easier and cheaper to apply than conventional coatings made directly on the glass itself.

Delia believes that this work could inspire deliberate engineering of amorphous materials for other applications such as supercapacitors that store and release electrical energy rapidly and efficiently. The team’s next challenge is to develop a flexible material using their low-temperature process that meets or exceeds the best performance of electrochromic materials made by conventional high-temperature processing.

Delia says: "We want to see if we can marry the best performance with this new low-temperature processing strategy".

Milk-based edible packaging means you could have your cereal and eat the packing too!

Researchers are in the process of developing a biodegradable, edible packaging product made from milk proteins. Their aim is to replace plastic wrapping on foods like cheese and single serve beverage pods. And according to the researchers, it’s actually up to 500 times better than plastic at keeping oxygen from wrapped food.

Research chemical engineer Laetitia M. Bonnaillie of the U.S. Department of Agriculture explained that the casein-based film could be on the shelves within three years. Laetitia noted that casein, a protein readily available in the U.S. due an excess in milk production, already lends its sturdy properties to products like glue and plastic.

See this video for more information:

Sewage fuels hydrogen-powered cars

Drivers of hydrogen fuel cell vehicles in Japan, like the Toyota Mirai and Honda Clarity, can now fuel up at a ‘toilet-to-tank filling station’. The station is open only 12 hours per day but already is making enough hydrogen to fill 65 cars daily. That number could grow to 600 cars if all the biogas at the plant was harnessed.

The station in Fukuoka, Japan, is fuelled by biogas coming from a combination of methane and carbon dioxide produced by the breakdown of wastewater from a central sewage plant. It’s now the second of its kind, following a demonstration facility that used similar technology at a Fountain Valley, California, US, wastewater plant that started in 2011 and is no longer in operation.

The Fukuoka plant comes from a $12-million investment from Japan’s government, plus research, engineering, design and building work by Mitsubishi, Toyota, and Kyushu University. Starting in late 2015, fuel cell vehicle drivers have been able to go to the sewage plant and fuel up their cars.

Stanford-led team reveals nanoscale secrets of rechargeable batteries

Better batteries that charge quickly and last a long time have long been the goal for engineers. But despite decades of research and innovation, a fundamental understanding of exactly how batteries work at the smallest of scales has remained elusive. Researchers at Stanford University have been working on solving this problem.

The work, published in the Journal Science, has found a way to delve into the electrochemical reaction that fuels the most common rechargeable cell in use today: the lithium-ion battery.

By visualising the fundamental building blocks of batteries – small particles typically measuring less than 1/100th of a human hair in size – the team members have illuminated a process that is far more complex than once thought. Both the method they developed to observe the battery in real time and their improved understanding of the electrochemistry could have far-reaching implications for battery design, management and beyond.

If you have a research story to share, get in touch with the IChemE Blog Elves and you could be featured in next month’s post.