Five chemical engineering research stories from July 2016

31st July 2016

To help you stay up-to-date with the latest achievements from the chemical engineering research community here is our monthly installment with some of the latest stories.

Here are five stories of amazing chemical engineering research and innovation:

Making dirty water drinkable

The new approach combines bacteria-produced cellulose and graphene oxide to form a bi-layered biofoam. "The properties of this foam material that we synthesized has characteristics that enhances solar energy harvesting. Thus, it is more effective in cleaning up water," said Pratim Biswas, the Lucy and Stanley Lopata Professor and chair of the Department of Energy, Environmental and Chemical Engineering.

Newly designed portable device produces biopharmaceuticals on demand

Patient survival in remote locations is dependent on access to medicine. This is a major problem for medics on the battlefield and doctors in remote or developing parts of the world.

Researchers from MIT have designed a portable production system which can manufacture a range of biopharmaceuticals on demand. The paper published in the journal Nature Communications, the shows how the system can be used to produce a single dose of treatment from a compact device containing a small droplet of cells in a liquid.

Tim Lu, an associate professor of biological engineering and electrical engineering and computer science, and head of the Synthetic Biology Group at MIT’s Research Laboratory of Electronics said “Imagine you were on Mars or in a remote desert, without access to a full formulary, you could program the yeast to produce drugs on demand locally”.

Add CO2 to improve biofuel production

According to a preliminary economic analysis reported in the study, a CO2 -enhanced process could reduce costs by 50–65% compared with conventional pretreatment methods. Seema Singh, director of biomass pretreatment at JBEI, said: “Pretreatment is the most expensive part of the biofuels production process. If you count the whole production cycle, pretreatment is second only to the cost of growing and obtaining the feedstock itself.”

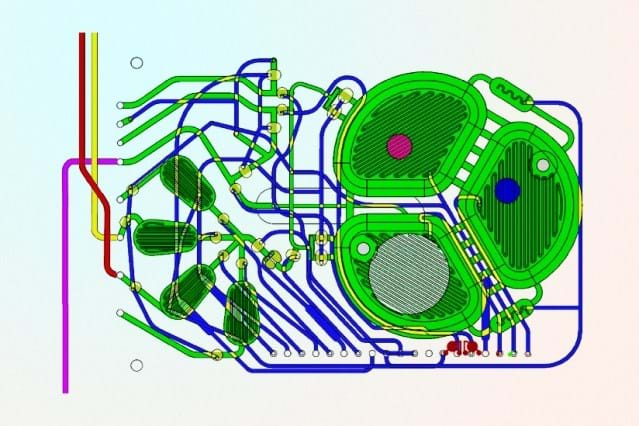

Engineers discover highly conductive materials for more efficient electronics

Their research, published in the scientific journal, APL Materials, was led by University of Utah electrical and computer engineering assistant professor Berardi Sensale-Rodriguez and University of Minnesota chemical engineering and materials science assistant professor Bharat Jalan. The teams work found that when two oxide compounds (strontium titanate (STO) and neodymium titanate (NTO)) interact with each other, the bonds between the atoms are arranged in a way that produces many free electrons, the particles that can carry electrical current. STO and NTO are by themselves are insulators and not conductive at all.

This innovation could greatly improve power transistors -- devices in electronics that regulate the electrical current -- by making power supplies much more efficient for items ranging from televisions and refrigerators to handheld devices. "When I look at the future, I see that we can perhaps improve conductivity by an order of magnitude through optimizing of the materials growth," Bharat says. "We are bringing the possibility of high power, low energy oxide electronics closer to reality."

Inspired by Octopuses

After studying the suction capabilities of octopus tentacles, they think that a tentacle-inspired bio-adhesive could meet all these criteria. According to the team, “Flexible pressure sensors might give future prosthetics and robots a better sense of touch; building them requires a lot of laborious transferring of nano- and microribbons of inorganic semiconductor materials onto polymer sheets.”

If you have a research story to share, get in touch with the IChemE Blog Elves and you could be featured in next month’s post.