Smart bandage could save lives (Day 295)

18th March 2015

When someone suffers a serious injury, timing can literally be a matter of life or death. Blood loss must be tackled immediately, but care must also be taken to prevent infection of the wound.

Chemical engineers working at Massachusetts Institute of Technology (MIT) have developed a dual-function ‘smart bandage’ that could save lives, not only by stopping bleeding but also by preventing infection.

The bandage is designed to rapidly dispense a coagulating agent that stops bleeding and then slowly release an antibiotic to prevent infection. This work is published in the journal ACS Biomaterials Science and Engineering under the title: Multifunctional Self-Assembled Films for Rapid Hemostat and Sustained Anti-infective Delivery.

The group developing these smart bandages is led by Professor Paula T. Hammond, the David H. Koch Chair Professor of Engineering in the Chemical Engineering Department at MIT. Paula suggests that the bandages might prove particularly effective in the treatment of wounded soldiers on the battlefield when a medic is not present.

Paula and her lab have been working on the product for several years. Initially they used a process called layer-by-layer assembly to create hemostatic films, just micrometres or even nanometres thick, by spraying or dipping objects in a water-based solution which the drug. This enabled them to produce films that were able to release one drug at a time.

But Paula wanted to create a bandage that could release multiple drugs at different rates. This proved to be much more difficult. “If the clotting agent and the antibiotic come out at the same rate, it’s too slow to stop the bleeding and not a sustained enough release of the antibiotic to prevent infection,” Paula says.

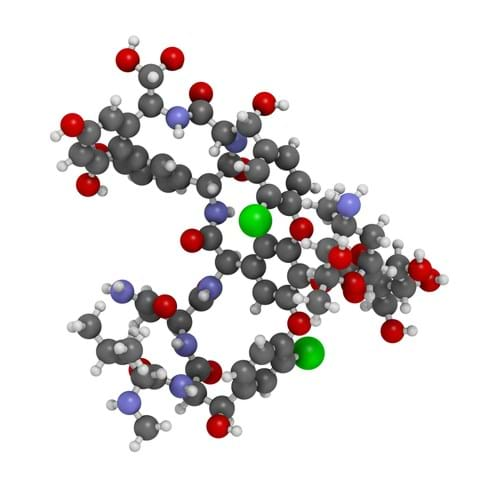

A major issue they faced was that the conditions used to create a Thrombin coating (the blood clotting agent) would damage an underlying Vancomycin (antibiotic) film.

Instead, the team found a way to stabilise the antibiotic coating by covalently attaching Vancomycin to poly(β-L-malic acid) (PMLA). The Vancomycin-PMLA film stays in place even when it’s coated with thrombin. More importantly, the PMLA links to Vancomycin in a manner that doesn't interfere with the antibiotic’s ability to kill bacteria.

Paula and her group then tested Vancomycin-PMLA and Thrombin coated gelatin sponges. As the supporting polymers in the film dissolve, most of the Thrombin is released immediately. However, the Vancomycin coupled to PMLA is released more slowly over the course of 24 hours – exactly what Paula was looking for.

The next stage is to trial these bandages and see how well they work. Paula is keen to test out different drug combinations, such as painkillers, to see how wide-ranging this approach could be.

It's often easy to see how the chemical engineering skill set relates to energy, water and food, but this is a wonderful example of a chemical engineer applying their fundamental thinking to a product that could make a big difference in a health care setting, saving lives in the process.

I wish Paula and the rest of her team the best of luck with their future work.

If you are working to create a versatile healthcare product, why not get in touch and tell me your story.